Anti-Static PE Foam Selection Guide

------Core Differences and Application Scenarios of EPE, EVA, and IXPE

1. Basic Characteristics Comparison

|

Property |

EPE FOAM |

EVA FOAM |

IXPE FOAM |

|

Material Composition |

Expanded Polyethylene |

Ethylene-Vinyl Acetate |

Cross-linked Polyethylene |

|

Density |

25-30kg/m³ |

60-65kg/m³ |

40-45kg/m³ |

|

Anti-Static Performance |

0^9-10^11Ω |

10^5-10^9Ω |

10^5-10^9Ω |

|

Color |

Red |

Black |

Black |

|

Surface Texture |

Soft, |

Soft, |

Smooth, |

|

Compressive Strength |

Low |

High (impact-resistant) |

High |

|

Temperature Range |

-40~80℃ |

-50~100℃ |

-60~120℃ |

2. Core Differences Analysis

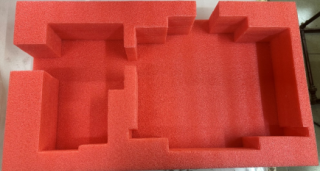

(1). EPE Foam (Expanded Polyethylene)

- **Advantages**:

- Lightweight and soft (density 25-30kg/m³), excellent cushioning and shock absorption, suitable for protecting fragile items.

- Low cost, ideal for large-scale packaging needs.

- **Limitations**:

- Short anti-static lifespan (3-6 months), prone to deformation under long-term pressure, not suitable for heavy-duty stacking.

- **Recommended Applications**:

✅ Packaging for electronic products (e.g., phones, tablets) during shipping.

✅ Temporary anti-static packaging for lightweight instruments.

✅ Budget-sensitive applications with short-term anti-static needs.

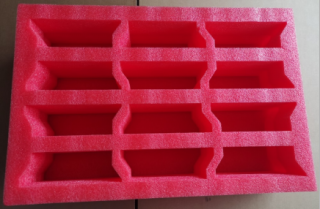

(2).EVA Foam (Ethylene-Vinyl Acetate)

- **Advantages**:

- Higher density (60-65kg/m³), balanced elasticity and firmness, wear-resistant, tear-resistant, and can be customized into complex shapes.

- Permanent anti-static (10^5-10^9Ω), excellent waterproof and moisture-proof properties.

- **Limitations**:

- May shrink slightly at high temperatures and degrade with prolonged outdoor exposure.

- **Recommended Applications**:

✅ Precision instrument linings (e.g., cameras, optical equipment).

✅ Custom anti-static inserts for toolboxes.

✅ Industrial applications requiring both cushioning and support.

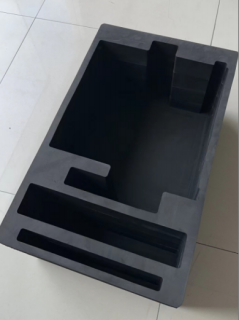

(3). IXPE Foam (Cross-linked Polyethylene)

- **Advantages**:

- Moderate density (40-50kg/m³), closed-cell structure, strong pressure resistance, and long-term durability without deformation.

- Permanent anti-static (10^5-10^9Ω), resistant to high/low temperatures and corrosion, with stable anti-static performance.

- **Limitations**:

- Higher cost and more complex manufacturing process.

- **Recommended Applications**:

✅ Long-term storage of high-end electronic components (e.g., chips, circuit boards).

✅ Packaging for medical devices and aerospace precision instruments.

✅ Anti-static needs in high-temperature/humidity environments.

3. Selection Decision Tree

(1). Is your usage environment harsh?

- High temperature/humidity/corrosive environments → **IXPE**

- Normal environments → Choose **EPE** or **EVA** based on budget and load requirements.

(2). Do you need long-term anti-static performance or repeated use?

- Long-term anti-static → **EVA** or **IXPE**

- Short-term anti-static (3-6 months) → **EPE**

(3). What is your budget priority?

- Cost-sensitive → **EPE**

- Balanced cost-performance → **EVA** or **IXPE** (similar prices, choose based on processing method)

4. Summary Recommendations

- **EPE**: Economical and practical, suitable for lightweight, short-term protection with limited anti-static lifespan (3-6 months).

- **EVA**: Versatile and durable, permanent anti-static, ideal for medium-pressure and customized needs.

- **IXPE**: High-end and long-lasting, permanent anti-static, suitable for harsh environments and long-term protection.

-**Price Note**: EVA and IXPE materials are similarly priced, but specific costs depend on processing methods and market supply-demand dynamics. Choose based on actual needs.

For further sample testing or technical consultation, please contact our team!

Company: Yufa Polymer Products Co., Ltd.

Email: info@yufapolymer.com

Website: www.yufapolymer.com