With the widespread use of electronic products and precision equipment, antistatic packaging has become a key factor in ensuring product safety. However, finding ways to reduce packaging costs while maintaining effective antistatic protection is an important challenge for many businesses. To address this need, we are introducing Antistatic EPE Foam as your ideal solution.

Why Choose Antistatic EPE Foam?

1. Excellent Antistatic Properties

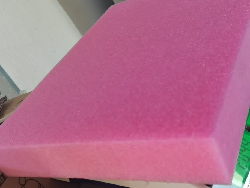

Our antistatic EPE foam uses advanced antistatic treatment technology, effectively suppressing static electricity buildup and preventing electrostatic discharge (ESD) damage to sensitive electronic components. Whether in transit or storage, it ensures full protection for your products.

2. Cost-Effective

Compared to other high-end antistatic materials, antistatic EPE foam offers a much lower cost, making it perfect for environments where temperature and humidity are relatively stable, and the required duration of antistatic effectiveness does not exceed one year. It provides an economical solution for businesses to maintain product safety while reducing packaging costs.

3. Lightweight and Durable

Antistatic EPE foam not only offers excellent antistatic properties but also provides superior cushioning to protect products from external shocks during transportation. Its lightweight nature further reduces transportation and storage costs.

4. Adaptable to Various Environmental Conditions

Antistatic EPE foam is particularly suitable for environments with controlled temperature and humidity. Under stable temperature and humidity conditions, its antistatic properties can last up to one year, making it ideal for long-term storage and transportation of electronic products.

Our Services for You

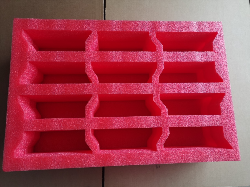

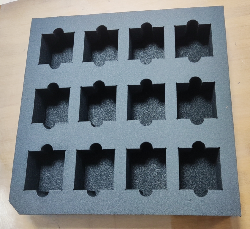

· Custom Production: We offer customized sizes, thicknesses, and shapes of antistatic EPE foam to meet various packaging requirements.

· Sample Testing: Before placing a bulk order, we provide samples for you to test and ensure that the antistatic performance meets your expectations.

· Flexible Production and Delivery Timelines: We offer flexible production schedules and fast delivery services to ensure your orders are completed on time.

Recommendation: In Environments with Unstable Conditions and Higher Antistatic Requirements

While antistatic EPE foam performs excellently in controlled environments, if your working environment is less predictable or if you have stricter antistatic requirements, we recommend using Black Antistatic XLPE Foam as the packaging material. Black Antistatic XLPE Foam offers superior antistatic performance, especially in high humidity or fluctuating temperature environments, ensuring long-lasting protection for your electronic products from static damage.

Let us provide you with the most suitable antistatic packaging solution, ensuring the safety of your products while reducing your packaging costs!.

Email: info@yufapolymer.com

Website: www.yufapolymer.com

Protect your devices, minimize damage, and extend their lifespan.