In modern electronic manufacturing, especially in Surface Mount Technology (SMT) production lines, precise component loading and unloading operations are essential for ensuring production efficiency and product quality. To meet this need, we introduce the Belt Adjustment ESD Magazine Rack, designed specifically for precise handling and electrostatic protection of electronic components, helping you achieve efficient, stable, and safe operations in your production process.

Product Highlights

1. Powerful Electrostatic Protection

Our ESD Magazine Rack is designed with high-quality anti-static materials that effectively prevent static charge build-up, protecting sensitive electronic components from electrostatic damage. In SMT production, static electricity is one of the main causes of component damage. By using our ESD magazine rack, you can confidently address this challenge.

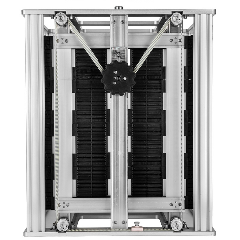

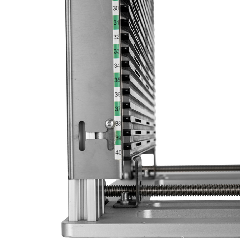

2. Precise Belt Adjustment (Lead Screw Adjustment) Mechanism

The innovative belt adjustment and lead screw adjustment mechanism allows for precise vertical and horizontal positioning of the rack according to production needs. This adjustment feature ensures smooth and accurate placement and removal of components, accommodating various component sizes and PCB specifications with ease.

3. Smooth and Efficient Operation

With the belt-driven system, the rack ensures smooth operation during adjustments, reducing friction and wear while maintaining precision. This design enhances the durability and reliability of the equipment, while increasing production efficiency by reducing time spent on manual adjustments.

4. Stable and Durable Frame

The aluminum alloy frame provides structural stability for the rack. It is both lightweight and durable, capable of enduring high-intensity use in SMT production lines. The frame is resistant to corrosion and wear, ensuring long-term stability and reliable performance.

5. Increased Production Efficiency and Reduced Operational Difficulty

The precise lead screw adjustment and efficient belt-driven system reduce the time required for repositioning, making the component handling process more convenient and less prone to errors. This increases the overall efficiency of the production line, while easing the workload of operators.

6. Versatility and Flexibility

The adjustable design of the ESD magazine rack ensures compatibility with various component sizes. It can be used for different types of SMT production lines and electronic assembly processes, offering exceptional flexibility for handling various components during production.

Applications

· SMT Production Lines: This rack is specifically designed for precise loading and unloading of components, ensuring smooth operation in the SMT assembly process.

· PCB Assembly: Ideal for loading and unloading PCB components, ensuring that components are placed and removed with precision and without damage.

· Electronic Component Handling: Used in industries dealing with sensitive components like semiconductors, capacitors, resistors, and integrated circuits, where electrostatic discharge protection is critical.

Why Choose Our ESD Magazine Rack?

· Powerful Electrostatic Protection:

Made from high-quality anti-static materials, the rack provides long-lasting electrostatic protection, ensuring that sensitive components are protected from ESD damage, and maintaining high-quality standards throughout production.

· High Precision Adjustment:

The lead screw adjustment mechanism enables precise handling of components, adapting to different handling needs and ensuring accurate loading and unloading.

· Smooth and Efficient Operation:

The belt-driven system ensures smooth operation, enhancing production efficiency by minimizing time spent on manual adjustments.

· Stable and Durable:

The aluminum alloy frame ensures a lightweight yet robust structure, capable of enduring long-term, high-intensity use while maintaining its performance.

· Versatile and Flexible:

Designed to accommodate various component sizes, the rack offers flexible adaptability to different types of SMT production lines and electronic assembly needs.

Conclusion

Choose our Belt Adjustment ESD Magazine Rack to enhance the precision, efficiency, and safety of your SMT production lines. Whether for PCB assembly, electronic component handling, or sensitive electronic manufacturing, this rack provides optimal electrostatic protection and precise handling for your components, ensuring smooth operations in every environment.

Contact us now to learn more about customized solutions with our ESD magazine rack, and let us provide your production line with the most professional and comprehensive support.

Email: info@yufapolymer.com

Website: www.yufapolymer.com

Increase production efficiency, protect your equipment, and ensure high-quality results with our ESD magazine rack!

1. Install the rack and ensure that it fits snugly with the base plate

2. Fix the 4 pillars with screws

3. Align the fixed side panel with the hole and tighten the screws

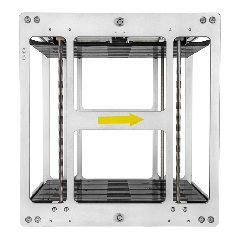

4. The bottom of the activity side panel is tightly attached to the edge of the rack

5. Install the bottom plate, push the round pin of the buckle upwards, and then move the side plate

6. Install the gear lever downwards at the spring position to complete the installation

Special note: In steps 4 and 5, it should be noted that the circular pin of the buckle is precisely aligned with the circular hole of the bottom plate, and the positioning here must be accurate. The up, down, left, and right must be synchronized, otherwise it will cause tooth jumping.