Why Smart Workstations Now Require Dual-Function Flooring Systems

✍️ Original article by YUFA Polymer. For inquiry or redistribution, please contact: info@yufapolymer.com

�� Production Site: 3rd Floor, Building E, North Yongfa Shangliao Park, Baoan District, Shenzhen, Guangdong, P.R. China

⏳ 1. Context: Why ESD Matting Needs to Evolve

In fast-paced electronics manufacturing and cleanroom assembly lines, personnel often stand for extended periods while handling static-sensitive components. Traditional ESD mats or general-purpose fatigue mats can only address part of the problem — either static dissipation or physical fatigue.

The modern answer? A multi-layered ESD anti-fatigue mat with ergonomic, static-dissipative, and anti-slip performance. Our Iron-Plate Pattern ESD Mats combine long-term worker comfort with strict electrostatic discharge protection — making them a smart investment for environments where health, safety, and compliance intersect.

�� 2. Industry Use Cases: Who Needs These Mats?

Our ESD Anti-Fatigue Mats are trusted across sectors where static and prolonged standing coexist:

• Electronics Assembly & SMT Lines:

Reduces foot fatigue during long shifts and protects sensitive PCBA from ESD.

• Semiconductors & Photonics Labs:

Maintains a clean, static-safe zone under microscopes, testers, and packaging stations.

• Medical Devices & Cleanroom Applications:

ESD-safe underfoot comfort in ISO-certified and Class 100–1000 cleanroom zones.

• Packaging & Logistics Stations:

Used in antistatic shipping areas or QC inspection zones for standing operators.

⚙️ 3. Why Choose Multi-Layered Anti-Fatigue Mats Over Single-Layer Options?

1. Permanent ESD Protection

Surface resistance consistently between 10⁴–10⁸ Ω, even with foot traffic and long-term use.

2. Triple-Layer Ergonomic Build

• Top: Textured PVC with iron-plate embossing

• Middle: EPDM FOAM core / High-density PU foam core

• Bottom: Anti-slip rubber backing for stability

3. Industrial-Grade Durability

Soft but not collapsible. Engineered for non-deformation over months of heavy use.

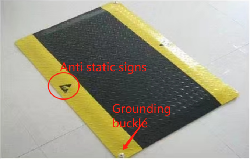

4. Color & Safety Options

Available in black, gray, blue, green, with optional yellow warning edges to enhance visual safety in work zones.

�� 4. Technical Specifications & Customization

Standard Structure:

• Surface: PVC with iron-plate embossing

• Middle Layer: EPDM foam / PU foam

• Bottom: Anti-slip adhesive backing

Key Parameters:

• Thickness: 10–40 mm

• Surface resistance: <10⁹ Ω

• Available Colors: Black, gray, blue, green (yellow edges optional)

• Standard Size: 600 × 900 mm (custom sizes available)

Optional Add-ons:

• Corner grounding snaps

• QR-coded branding labels

• Modular interlock edges for wide floor coverage

�� 5. How to Justify the Upgrade to Decision Makers?

Some buyers may view anti-fatigue mats as generic accessories, but operational feedback tells a different story:

• ��♂️ Reduced absenteeism due to muscle strain

• �� Improved productivity during long shifts

• ✅ Compliance-ready for ESD audits (ANSI/ESD S20.20)

• �� Longer service life compared to foam-only mats

• �� Multi-functionality = fewer procurement SKUs

When presented as part of an integrated ESD control plan and ergonomics initiative, these mats become a compliance and cost-efficiency win.

�� 6. Final Thought: Rethink Your Factory Floor

Anti-fatigue floor mats shouldn’t just cushion feet — they should protect your products, support your teams, and ensure regulatory compliance.

Our Iron-Plate ESD Anti-Fatigue Mats are more than flooring — they’re part of your productivity infrastructure.

�� Contact us now to explore sizing, branding, and trial deployment:

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com

�� Address: 3rd Floor, Building E, North Yongfa Shangliao Park, Baoan District, Shenzhen, Guangdong, P.R. China