Why Rotational Molding Expands the Possibilities for ESD-Safe Packaging

✍️ Original article by YUFA Polymer

�� For inquiries: info@yufapolymer.com

�� Production Site: Shenzhen, China

1. Why Standard Packaging Fails for PCBA

When it comes to storing, transporting, or packaging PCBA, no single solution works for everyone. Some need higher load-bearing strength, others need enhanced shock absorption. Some require higher slot density to maximize capacity, while others seek cost-effective, reusable systems. And nearly all demand reliable ESD protection with custom-fit configurations.

That’s why off-the-shelf packaging isn’t enough. The answer? Custom-engineered anti static packaging solutions designed specifically for your products..

�� 2. How We Solve PCBA Packaging Challenges

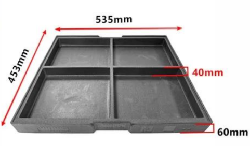

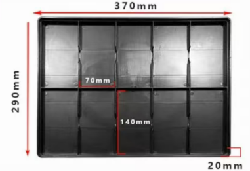

At YUFA Polymer, we design ESD box and ESD tray systems that adapt to your requirements:

· Higher load capacity → Use 4mm ESD honeycomb board instead of standard 5mm corrugated sheet for stronger partitions.

· Shock resistance → Combine ESD EVA foam with honeycomb or corrugated dividers for both cushioning and stability.

· Higher slot density → Precision-cut knife dividers allow for more parts per tray without compromising protection.

· Better cost-performance → Reusable, recyclable designs reduce long-term logistics cost.

· Full ESD protection → Surface resistance 10⁴–10⁹ Ω ensures compliance across EPA standards.

⚙️ 3. Case Study: From Generic to Tailored

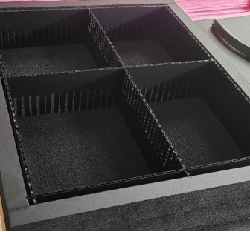

One customer required trays with dividers <5mm wide and slot depth >50mm for PCBA modules. Traditional EVA foam trays lacked the necessary support. Our solution? A hybrid design:

· Sidewalls and base: ESD EVA foam for cushioning.

· Internal dividers: ESD honeycomb sheets for rigidity.

The result: trays that provided both stability and electrostatic protection while extending service life.

�� 4. Why Choose YUFA Polymer?

· Versatile material expertise – From EVA foam to honeycomb sheets, we select the right materials for your needs.

· Proven customization – Dozens of successful PCBA projects across electronics, semiconductor, and optics industries.

· Customer-first design – Every ESD box and ESD tray is engineered to solve your unique challenges, not just to fit a standard mold.

�� 5. Final Thought: Personalized Packaging, Real Value

Whether you want to solve load capacity issues, improve shock resistance, increase storage density, lower total cost, or achieve full anti static packaging compliance—we can design it.

✨ At YUFA Polymer, we don’t just supply boxes and trays—we deliver tailored PCBA packaging solutions that protect your products, optimize logistics, and align with your business goals.

�� Ready to explore custom designs? Contact us at info@yufapolymer.com