In SMT (Surface Mount Technology) production, choosing the right reel size and storage solution plays a critical role in material management, space utilization, and production efficiency.

Among all reel sizes, 7 inch and 13 inch SMT reels are the most commonly used in electronics manufacturing.

This article compares their storage capacity and space efficiency, helping SMT engineers and purchasing teams select the right ESD reel storage solution.

1. Understanding 7 Inch and 13 Inch SMT Reels

�� 7 Inch SMT Reels (180mm)

7 inch reels are widely used for:

· Line-side material storage

· High-mix, low-volume production

· Frequent component changeovers

They are lightweight, easy to handle, and ideal for SMT production lines and workstations.

�� 13 Inch SMT Reels (330mm)

13 inch reels are typically used for:

· High-volume production

· Bulk component storage

· Central warehouses and kitting areas

They offer higher component capacity per reel, but require more storage space.

2. Storage Capacity Comparison

Choosing the right reel storage solution is not only about reel size, but also about how many reels can be stored efficiently in one unit.

�� Storage Capacity Comparison

|

Reel Size |

Storage Solution |

Capacity |

|

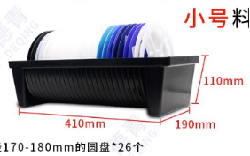

7 Inch |

ESD SMT Reel Storage |

Up to 30 reels |

|

7 Inch (Compact) |

Compact ESD Reel Holder |

Up to 26 reels |

|

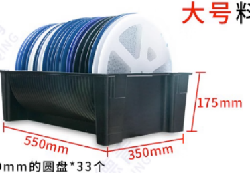

13 Inch |

ESD SMT Reel Storage Box |

Up to 33 reels |

These capacities are designed to maximize storage efficiency while maintaining ESD protection and easy access.

3. Space Utilization and Layout Efficiency

�� 7 Inch Reel Storage – Space Saving Advantage

7 inch reel storage solutions are ideal for environments where:

· Floor space is limited

· Fast material access is required

· Line-side storage is needed

Storing up to 30 reels in one compact unit helps reduce clutter and improves operator efficiency on SMT lines.

�� 13 Inch Reel Storage – High Density Storage

13 inch reel storage boxes are better suited for:

· Centralized material storage

· Kitting and preparation areas

· High-volume production environments

With a capacity of up to 33 reels, this solution offers high-density storage without compromising ESD safety.

4. ESD Protection in Reel Storage

Regardless of reel size, ESD protection is essential.

A reliable ESD SMT reel storage solution should provide:

· Surface resistance between 10⁶–10⁹ Ω

· Stable material performance

· Compatibility with ESD-controlled environments

Both 7 inch and 13 inch reel storage solutions discussed here meet these ESD requirements, making them suitable for electronics manufacturing in Japan and Europe.

5. Which Reel Storage Should You Choose?

✅ Choose 7 Inch Reel Storage if:

· You need fast access at SMT production lines

· You handle high-mix components

· Space efficiency is a priority

✅ Choose 13 Inch Reel Storage if:

· You focus on high-volume production

· You require centralized material storage

· Maximum reel capacity per unit is needed

In many SMT factories, both 7 inch and 13 inch reel storage solutions are used together to optimize the entire production workflow.

6. Conclusion

There is no one-size-fits-all solution when it comes to SMT reel storage.

The right choice depends on reel size, storage capacity, and available space.

By using:

· 7 inch ESD SMT reel storage (up to 30 reels)

· 13 inch ESD SMT reel storage boxes (up to 33 reels)

SMT manufacturers can achieve better organization, improved ESD protection, and higher production efficiency.

�� Call to Action

Looking for ESD SMT reel storage for 7 inch or 13 inch reels?

Contact us today for specifications, bulk pricing, and a fast quotation.

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com