——An Upgrade from Traditional ESD Corrugated Plastic Boxes

✍️ Original article by YUFA Polymer.

�� For inquiry, please contact: info@yufapolymer.com

�� Production Site: Shenzhen, China

In electronics manufacturing, ESD packaging is not only used for protection — it is part of the production and logistics system.

Traditional 5mm ESD corrugated plastic boxes are widely used, but as product size, weight, and reuse cycles increase, their limitations become more apparent.

To address these challenges, ESD plastic honeycomb boxes are increasingly adopted as an upgraded solution.

Why Upgrade from ESD Corrugated Plastic Boxes?

ESD corrugated plastic boxes work well for light-duty applications. However, issues may arise when:

· Box size becomes larger

· Load weight increases

· Long-term reuse is required

· Dimensional stability is critical

Under these conditions, deformation, reduced rigidity, and shorter service life can affect handling efficiency and packaging reliability.

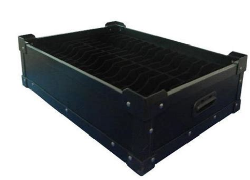

What Are ESD Plastic Honeycomb Boxes?

ESD plastic honeycomb boxes are manufactured from 4mm permanent ESD polypropylene (PP) honeycomb panels.

This material is specifically developed as an upgrade alternative to traditional 5mm ESD corrugated plastic sheets, offering improved mechanical strength and stability.

The honeycomb panels are produced using a three-layer co-extrusion process, ensuring permanent ESD performance throughout the material rather than surface treatment.

Electrical Properties

The ESD performance of the honeycomb panels is stable and permanent:

· Surface resistivity: 10⁴–10⁸ Ω

· Volume resistivity: 10⁴–10⁸ Ω

· Permanent ESD, suitable for electronics manufacturing environments

This resistivity range meets ESD protection requirements without emphasizing conductive behavior.

Key Advantages in Electronics Manufacturing

Compared with ESD corrugated plastic boxes, ESD plastic honeycomb boxes provide:

· Higher rigidity and load-bearing capacity

· Better dimensional stability for large-size boxes

· Longer service life in reusable packaging systems

· Permanent ESD performance without coating

· Customizable structure compatible with existing workflows

They are especially suitable for demanding WIP circulation and internal logistics.

Typical Applications

ESD plastic honeycomb boxes are commonly used for:

· PCB and PCBA handling

· Electronic modules and assemblies

· Large or heavy electronic components

· Factory internal logistics and reusable packaging systems.

Custom Design and Replacement Support

These boxes are usually custom-designed.

Manufacturers can:

· Match existing box dimensions

· Reinforce load-bearing areas

· Optimize structure for stacking and handling

This allows factories to upgrade packaging performance without changing production processes.

Conclusion

ESD plastic honeycomb boxes are not intended to replace all ESD packaging solutions.

They are a strategic upgrade for applications where strength, durability, and dimensional stability are critical.

For electronics manufacturers facing higher load requirements and longer reuse cycles, they provide a reliable and scalable solution.

Call to Action

If you are evaluating ESD plastic honeycomb boxes as an upgrade to your existing ESD corrugated plastic boxes,

send us your drawings, samples, or basic requirements for review.

Our engineering team will provide technical feedback and a tailored solution.

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com