Why Custom-Matched Anti-static Inserts Are Now Essential in Smart Manufacturing

✍️ Original article by YUFA Polymer. For inquiry or redistribution, please contact: info@yufapolymer.com.

�� Production Site: 3rd Floor, Building E, North Yongfa Shangliao Park, Baoan District, Shenzhen, Guangdong, P.R. China.

⏳ 1. Context: Why Divider Optimization Matters More Than Ever

In an era of automated precision manufacturing and global logistics, traditional “one-box-fits-all” packaging solutions no longer suffice. The increasing complexity of electronic components—from automotive ECU modules to high-speed communication optics—demands not just protection, but contamination-free, ESD-safe, and easily traceable transport environments.

The answer? A new generation of anti-static honeycomb dividers. Lightweight, structurally stable, and highly customizable, they are becoming the backbone of modern electronics packaging—especially in applications where damage from electrostatic discharge (ESD), vibration, or contamination can translate to millions in loss.

�� 2. Industry Use Cases: Who Needs Anti-Static Honeycomb Dividers?

Anti-static honeycomb dividers (a.k.a. ESD knife-type partitions) are now widely adopted across several high-reliability industries:

· Automotive electronics: For safe in-plant logistics of ECU, TCU, or battery control units.

· Semiconductors & optics: For precision handling of optical lenses, wafers, and laser modules.

· Consumer electronics: For transport of finished devices and high-value PCBA assemblies.

· Medical & laboratory: As contamination-free transport containers for diagnostic modules.

· Smart manufacturing: Used as ESD-safe nesting inserts in returnable totes and AGV-compatible containers.

⚙️ 3. Why Use Dedicated Anti-Static Dividers Instead of Generic Inserts?

There are four reasons custom-configured honeycomb dividers outperform general partitions:

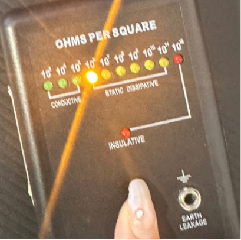

1. Permanent anti-static performance (10⁶–10⁹ Ω), independent of humidity or wear.

2. Modular structure design allows for single-layer, double-layer (folded), or EVA-wrapped assemblies.

3. Precision slotting enables tailored fit to component dimensions, avoiding micro-collisions or tilt.

4. Material compliance with ESD, ROHS, and cleanroom requirements ensures compatibility across facilities.

Moreover, standalone divider inserts provide the freedom to repurpose boxes, reconfigure slot geometry, and reduce unit cost across diverse SKUs—giving purchasing departments both flexibility and inventory efficiency.

�� 4. Technical Specification & Customization Options

Our standard honeycomb board features:

· Thickness: 4mm

· Basis weight: 1200g/m²

· Surface : Dual-sided anti-static

· Core: PP honeycomb cell structure (lightweight, high compression resistance)

· Configurations:

o �� Single-layer slotting: Cost-effective

o �� Double-layer folded: Greater strength for heavier payloads

o �� Wrapped with anti-static EVA: Enhanced surface friction and shock absorption

All materials are fully recyclable and available in black. Optional: PSA adhesive backings, QR-coded labeling, and ultrasonic edge sealing.

�� 5. How to Convince Stakeholders to Switch?

Buyers may hesitate to purchase dividers as standalone items, but successful case studies show:

· �� Reuse-ready: Removable inserts extend the life of outer boxes

· �� Lower total cost: Reduces breakage and rework from poor in-box fit

· �� Inventory consolidation: One box size, multiple insert options

· �� Shrink scrap ratio: Especially for Class 0 component logistics

Training teams to view dividers as part of the protective packaging strategy—not as a consumable—has proven key to procurement buy-in.

�� 6. Final Thought: Why It’s Time to Rethink ESD Packaging

In today’s manufacturing supply chain, every component, every handling step, every packaging layer matters. By deploying anti-static honeycomb dividers matched precisely to the application—not just the box—you gain control over what used to be your weakest link: in-transit component safety.

Let’s upgrade your packaging from sufficient to strategic.

�� Contact us now to customize your anti-static partition system:

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com

�� Address: 3rd Floor, Building E, North Yongfa Shangliao Park, Baoan District, Shenzhen, Guangdong, P.R. China.