In today’s rapidly advancing high-tech world, electrostatic discharge (ESD) has become a critical issue impacting various industries. From semiconductors and electronic components to automotive electronics and medical devices, static electricity can cause hidden damage to precision products, potentially leading to equipment malfunction or irreversible damage. To effectively address this challenge, we offer professional antistatic foam solutions, providing comprehensive electrostatic protection for your high-value products during transportation, storage, and packaging.

Why Choose Our Antistatic Foam?

1. Effective Protection, Reducing Electrostatic Damage

Our antistatic foam features exceptional electrostatic discharge resistance, effectively preventing ESD and protecting your electronic components from damage. This ensures that each product is delivered safely and intact.

2. Three Materials for Targeted Solutions

To meet the diverse needs of our clients, we offer three different types of antistatic foam, each with unique advantages suited to various industries and applications:

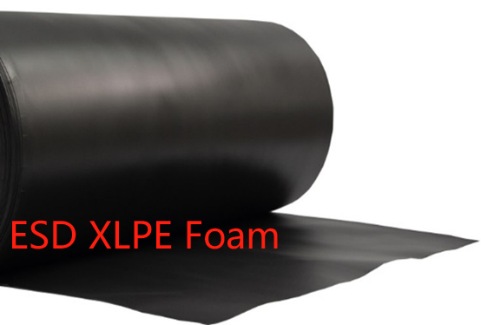

o XLPE Foam: Ideal for applications requiring high levels of electrostatic protection and stronger cushioning, such as packaging and transportation of precision instruments, medical devices, and semiconductor components. XLPE foam offers excellent electrostatic protection and high compressive strength, effectively reducing damage from vibrations.

o EVA Foam: Commonly used for packaging mobile accessories, consumer electronics, and similar products. It is soft, elastic, and provides good shock protection while also safeguarding against static electricity. EVA foam is suitable for multi-layer packaging, protecting against external impacts and compression.

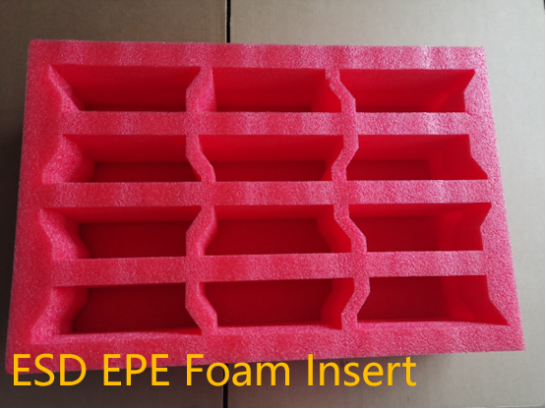

o EPE Foam: Suitable for large-volume packaging solutions, widely used in automotive electronics, home appliances, and photovoltaic equipment. It not only has excellent static protection but is also lightweight and offers high space efficiency, significantly reducing procurement costs.

3. Efficient Packaging, Lower Transport Costs

During the production, transportation, or storage of products, our antistatic foam provides efficient protection. Its outstanding cushioning performance reduces damage during shipping, while the reasonable packaging design saves space, improves logistics efficiency, and lowers transport costs.

4. Wide Range of Applications to Meet Industry Needs

Our antistatic foam is suitable for various industries, offering tailored protection solutions for each:

o Electronics Industry: Provides effective protection for semiconductors, ICs, PCBs, and other components, ensuring no static damage before leaving the factory. XLPE foam is highly recommended for this application.

o Consumer Electronics: Protects products such as mobile phones, televisions, and computers from static damage to sensitive components. EVA foam is ideal for this use.

o Automotive Electronics: Safeguards automotive batteries, sensors, and electronic control units (ECUs) during transportation and storage. EPE foam is recommended to reduce vibrations and external pressure during shipping.

o Medical Devices: Provides static protection for medical devices like pacemakers and monitors, ensuring they remain safe and undamaged. XLPE foam is recommended due to its superior static protection, suitable for sensitive equipment.

o Photovoltaic Industry: Protects solar cells and photovoltaic modules from electrostatic damage. EPE foam is recommended for its lightweight properties, making it ideal for bulk shipping of large products.

5. Eco-friendly Materials, Green Production

We use antistatic foam materials that comply with international environmental standards, ensuring that our products not only perform excellently but are also produced with a commitment to sustainability. Regardless of your product specifications, we can provide customized solutions to help your brand stand out in the market.

Say Goodbye to Static and Ensure Safe Delivery of Your Products!

In the fiercely competitive market, product quality and reliability determine brand value and customer trust. Antistatic foam is an essential tool for safeguarding your products. Whether you’re involved in manufacturing electronic products, automotive electronics, medical devices, or other high-tech industries, our antistatic foam offers the best protection solutions for your products.

Contact us today to experience the outstanding performance of our high-quality antistatic foam!

Company: Yufa Polymer Products Co., Ltd.

Email: info@yufapolymer.com

Website: www.yufapolymer.com

We look forward to working with you to protect high-tech products and embrace a safer, more efficient future!