Engineered Anti-Static Foam Inserts Built from 5mm IXPE

✍️ Original article by YUFA Polymer.

�� For inquiry, please contact: info@yufapolymer.com

�� Production Site: Shenzhen, China

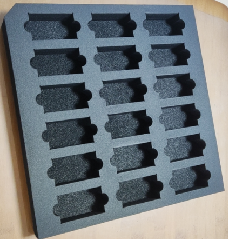

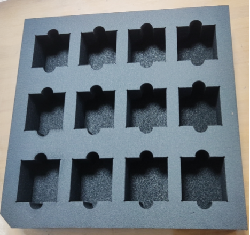

We design and manufacture custom ESD foam inserts for electronic products and assemblies, using 5mm anti-static IXPE foam as a modular base layer.

By layering, machining and assembling 5mm IXPE foam, we produce inserts with controlled geometry, stable ESD performance and repeatable quality, suitable for PCBs, PCBAs and electronic devices.

Typical prototype lead time: 5–7 working days.

→ Request a Quote or Technical Review

Packaging & Handling Requirements in Electronics Manufacturing

Electronic components and assemblies require packaging solutions that:

· Control electrostatic discharge consistently

· Hold products securely without deformation

· Maintain dimensional stability during transport and handling

· Support repeated use in production and logistics

Standard foam sheets or generic packaging often fail to meet these requirements when product geometry or handling conditions vary.

Custom ESD foam inserts are designed to match the exact shape and process needs of your electronic products.

Modular Construction from 5mm IXPE Foam

Our foam inserts are built starting from 5mm anti-static IXPE layers, instead of single thick foam blocks.

This modular construction allows:

· Flexible thickness control up to 300mm by lamination

· Step cavities, pockets and positioning features

· Improved dimensional repeatability across batches

· Predictable mechanical behavior under load

For electronics manufacturing, this approach supports consistent quality and scalable production.

Foam Processing & Manufacturing Capabilities

We produce ESD foam inserts using in-house equipment optimized for IXPE foam:

· CNC machining for precise cavities and cutouts

· Die cutting for consistent, repeatable shapes

· Vibration knife cutting for complex outlines

· Layer bonding, selective peeling and assembly

· Multi-layer foam insert construction

These capabilities support both rapid prototyping and volume production.

Design Support & Prototyping Process

With Drawings or Samples

· CAD files, PDFs or physical samples are reviewed

· Engineering feedback provided before prototyping

· Prototypes typically completed within 5–7 working days

Without Drawings

· Share product dimensions, weight and handling requirements

· Foam insert structure is designed based on use conditions

· Prototype provided for validation and approval

Our goal is to reduce iteration cycles and support efficient project launch.

Typical Electronics Applications

Custom ESD foam inserts are commonly used for:

· PCB and PCBA handling

· Electronic device and module transport

· Assembly, testing and inspection fixtures

· Reusable anti-static packaging solutions

Working Approach

Customers work with us because we provide:

If you are evaluating custom ESD foam inserts for electronic products,

send us your drawings, samples or basic requirements for review.

We will provide feedback on feasibility, structure and lead time.

→ Contact Us to Discuss Your Application

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com