Original article by YUFA Polymer.

�� For inquiry, please contact: info@yufapolymer.com

�� Production Site: Shenzhen, China

1. What Is a Hot-Pressed ESD EVA Foam Tray?

An ESD EVA foam tray is a thermoformed anti-static packaging solution designed for the storage, transport, and assembly of electrostatic-sensitive devices (ESDs).

Using a hot-pressing process, the EVA foam is molded under controlled temperature and pressure, forming a rigid yet resilient structure that combines the properties of both a plastic tray and cushioning foam.

Compared with traditional ESD boxes + EVA inserts, the hot-pressed EVA tray integrates both strength and shock absorption into a single structure — streamlining packaging, improving efficiency, and reducing assembly costs.

�� 2. Application Fields

The ESD EVA foam tray is widely adopted in industries requiring both static protection and physical stability:

· Semiconductor & Electronics – for PCBA, IC modules, sensors, and connectors

· AI Server & Communication Equipment – power modules, server blades

· Robotics & Automotive Electronics – battery controllers, optical sensors

· Medical & Laboratory Devices – contamination-free handling and precision assembly

In these fields, hot-pressed EVA trays outperform general ESD boxes by offering high load capacity, shock absorption, and repeatable use.

�� 3. How It Solves Common Customer Pain Points:

Customer Challenge Hot-Pressed EVA Tray Solution

Boxes require additional EVA inserts One-piece design — integrated cushioning & support

Weak structural strength of foam inserts Molded high-density EVA, 30–50% higher compression strength

Poor fit or frequent replacement Custom cavity design, reusable and dimensionally stable

Static discharge risk Permanent anti-static properties (10⁴–10⁹ Ω)

High logistics or rework cost Lightweight, recyclable, low maintenance

�� 4. Manufacturing & Customization

YUFA Polymer specializes in custom ESD foam trays using hot-press molding.

We design and manufacture according to your part geometry and factory workflow.

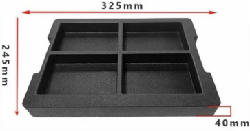

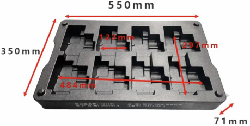

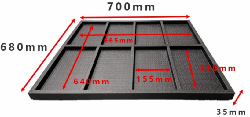

Customization options:

· Tray size and cavity layout

· Surface texture (smooth or embossed)

· Resistance value range (10³–10⁹ Ω)

· optional logo printing

· Stackable or nestable structure

Each tray undergoes resistance testing and dimensional inspection before shipment — ensuring reliability for high-end ESD management.

�� 7. Final Thoughts

If you’re still using a combination of ESD box + EVA insert, it’s time to rethink your strategy.

Our hot-pressed ESD EVA foam trays simplify logistics, reduce costs, and provide superior electrostatic protection — all in one integrated structure.

Let’s redefine your ESD packaging together..

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com