In the production, transportation, storage, and assembly of high-tech products, the safety of chips is crucial. This is especially true for electronic components exposed to high temperatures. Choosing a high-performance anti-static IC tray not only impacts the integrity of the chips but directly affects production efficiency and cost. Today, let’s dive into how selecting the right high-temperature anti-static IC tray can enhance the safety and reliability of chip transport, storage, and assembly.

1. Chip Protection Needs in High-Temperature Environments

During the manufacturing of modern electronic devices, chips face not only external environmental challenges such as temperature and humidity but also the need to perform complex automated assembly processes on efficient and precise production lines. Whether it’s QFN, BGA, QFP, SOP, DDR, or other package types, they all share one common characteristic: they need to maintain high performance and stability in extreme environments.

Problem 1: The Impact of High Temperatures on Chips

Chips in high-temperature environments are prone to physical damage. Specifically, solder joints and packaging materials are vulnerable to thermal expansion, which can lead to poor soldering or chip failure.

Problem 2: The Dangers of Static Electricity

Static discharge can instantly damage a chip’s internal circuitry, causing it to fail and resulting in significant losses.

2. How to Choose the Right High-Temperature Anti-Static IC Tray?

To address these challenges, a well-designed high-temperature anti-static IC tray can effectively solve these issues, offering the best protection for your chips.

· High-Temperature Resistance:

Our anti-static IC trays are made from high-temperature-resistant materials that can withstand temperatures up to 260°C. This ensures that your chips remain undamaged during transport and storage in high-temperature environments. Even in intense production conditions, the tray maintains its structural integrity, resisting deformation or cracking caused by temperature fluctuations.

· Anti-Static Protection:

Our trays feature an ESD protection design that effectively prevents static electricity from damaging chips. The anti-static resistance ranges from 10⁶ to 10⁹ ohms, far exceeding industry-standard electrostatic safety levels, ensuring your chips are protected from electrostatic interference.

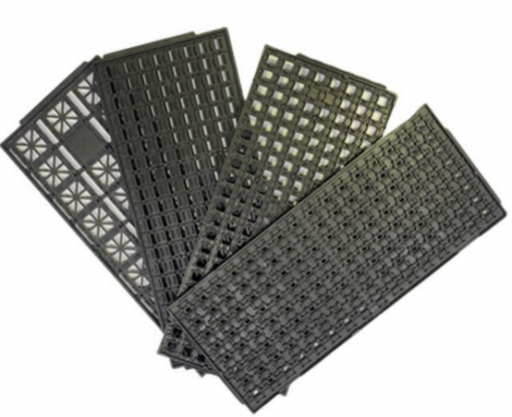

· Optimized Design for Perfect Compatibility with Various Packages:

Different package types, such as QFN, BGA, QFP, SOP, DDR, etc., have distinct requirements in terms of size, pin arrangement, and solder joint placement. Our trays are designed with precise, customized slot layouts that perfectly fit various chip packaging forms. For example, we design flat-bottomed slots for QFN packages, ensuring the stable placement of the bottom pads, and use grid-array slots for BGA packages, preventing pressure on the solder balls and preserving chip integrity.

· Efficient Automation Compatibility:

Our IC trays are specially designed for automated production lines. The precise slot design and smooth surface of the trays ensure seamless integration with pick-and-place systems, significantly improving production efficiency.

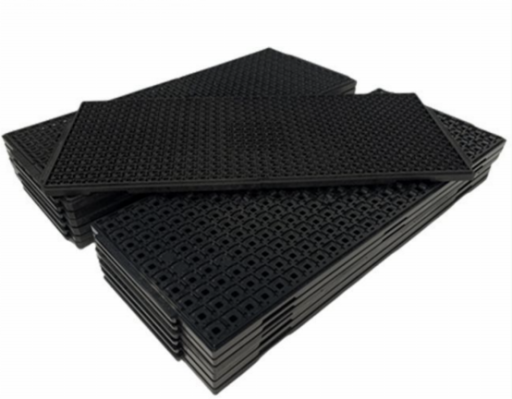

3. Product Performance and Quality

Our high-temperature anti-static IC trays undergo rigorous quality control, with each tray tested for both high-temperature and electrostatic protection to ensure they meet international quality standards. Here are some core advantages of our products:

· High-Temperature Resistance:

The trays can withstand prolonged exposure to high temperatures, ensuring no deformation at temperatures up to 160°C.

· Electrostatic Protection:

Each tray is equipped with effective ESD protection, safeguarding chips from electrostatic damage.

· Compression Resistance:

The trays can withstand considerable pressure during transport, preventing chip damage.

· Corrosion Resistance:

Made from high-strength plastic materials, the trays are resistant to acid and alkali corrosion, extending their service life.

· Flatness:

No more than 0.04 mm

4. Applications

Our trays are designed to effectively protect chips of various packaging types, including QFN, QFP, BGA, SOP, DDR, and more. They are widely used in electronic product production lines, storage warehouses, and transport processes.

5. Conclusion

Choosing a high-temperature anti-static IC tray not only protects your chips from external environmental damage but also enhances the automation efficiency of your production line, reducing manual intervention and improving overall production efficiency. In the complex and ever-changing environment of electronic product manufacturing, our trays provide comprehensive protection to ensure your chips always remain in optimal condition, avoiding unnecessary losses.

Contact us now!

Email: info@yufapolymer.com

Website: www.yufapolymer.com