——Permanent ESD & Conductive Packaging Built from 5mm / 850g Corrugated Plastic Sheet

✍️ Original article by YUFA Polymer.

�� For inquiry, please contact: info@yufapolymer.com

�� Production Site: Shenzhen, China

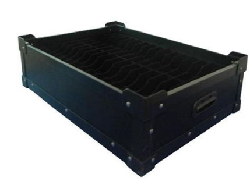

We design and manufacture custom ESD and conductive corrugated plastic boxes for electronics manufacturing and internal logistics, using 5mm, 850g permanent ESD or conductive PP corrugated plastic.

By precision cutting, folding, welding, and assembling corrugated plastic sheets, we produce reusable boxes with stable electrical performance, controlled structure, and repeatable quality, suitable for PCBs, PCBAs, electronic modules, and assemblies.

Typical sampling lead time: 5–7 working days.

→ Request a Quote or Technical Review

Packaging & Handling Requirements in Electronics Manufacturing

Electronic components and assemblies require packaging solutions that:

· Control electrostatic discharge consistently

· Protect products during handling and circulation

· Maintain dimensional stability under stacking and transport

· Support repeated use in production and logistics environments

Generic plastic boxes or surface-coated anti-static solutions often fail when used repeatedly or under varying handling conditions.

Custom ESD and conductive corrugated plastic boxes are designed to match exact product dimensions, handling processes, and ESD control requirements.

Modular Construction Using 5mm Corrugated Plastic Sheets

Our boxes are manufactured using 5mm, 850g PP corrugated plastic sheets, instead of generic injection-molded containers.

This construction method allows:

· Permanent ESD (10⁵–10⁹ Ω) or conductive (10³–10⁶ Ω) material selection

· Lightweight structure with sufficient rigidity for factory use

· Custom box sizes, heights, and internal layouts

· Consistent performance across repeated production batches

For electronics manufacturing, this approach enables scalable production and long-term reuse.

Box Processing & Manufacturing Capabilities

We produce ESD and conductive corrugated plastic boxes using in-house processing equipment optimized for PP sheets:

· Folding, riveting, and plastic welding

· Assembly of multi-panel box structures

· Integration of dividers, partitions, and internal supports

· Production of semi-finished or flat-pack components

These capabilities support both rapid prototyping and volume production.

Design Support & Prototyping Process

With Drawings or Existing Boxes

· CAD files, PDFs, or physical samples reviewed

· Structure and ESD performance evaluated

· Prototype completed typically within 5–7 working days

Without Drawings

· Share product dimensions, weight, and handling requirements

· Box structure designed based on usage conditions

· Prototype provided for validation and approval

Our goal is to minimize iteration cycles and support efficient project launch.

Typical Electronics Applications

Custom ESD and conductive corrugated plastic boxes are commonly used for:

· PCB and PCBA circulation

· Electronic component and module transport

· Work-in-process (WIP) storage

· Factory internal logistics and line-side handling

· Reusable anti-static packaging systems

Flat-Pack / Semi-Finished Shipping Options

For bulk or overseas orders, we offer semi-finished or flat-pack delivery.

This approach allows:

· Reduced shipping volume and logistics cost

· Local assembly without affecting ESD performance

· Efficient supply for EU and US customers

Flat-pack solutions are especially suitable for long-term, high-volume programs.

Working Approach

Customers work with us because we provide:

· A focus on custom ESD & conductive corrugated plastic boxes, not generic containers

· Engineering-oriented communication

· Clear and stable electrical performance classification

· Reliable prototype and production lead times

· Support for both short-term projects and long-term supply programs

We aim to operate as a technical manufacturing partner, not just a box supplier.

Start Your Custom ESD / Conductive Box Project

If you are evaluating custom ESD or conductive corrugated plastic boxes for electronics manufacturing,

send us your drawings, samples, or basic requirements for review.

We will provide feedback on structure, feasibility, and lead time.

→ Contact Us to Discuss Your Application

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com