After frequent business dealings with overseas customers, we deeply understand the troubles caused by the high shipping cost of our anti-static boxes. In order to reduce transportation costs, we have summarized three methods based on our previous experience, for those in need:

Option 1: Choose a good freight forwarding company to quote DDP prices

Freight: It can achieve relatively low prices for the same transportation method during the same period;

Transaction processing and timeliness: customers do not need to participate in any transaction, just wait for receipt. All transportation, customs clearance, taxation, and express delivery are completed by the freight forwarder throughout the entire process. The time limit is 2-5 days faster than the customer's own customs clearance and tax payment;

Purchase cost: As long as customers understand the product cost and DDP price, they can obtain the full purchase cost without any additional fees, making it convenient for customers to make budgets and decisions.

Option 2, product folding, reducing volume by 50-60%

Anti static corrugated folded box - Requires personnel and rivet machine equipment to participate in processing and assembly;

Anti-static reinforced corrugated box by assembly - Can be manually assembled without the need for equipment participation.

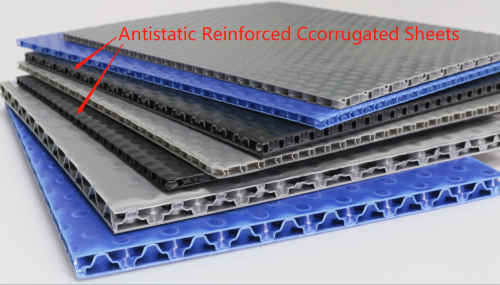

Image of anti-static reinforced board:

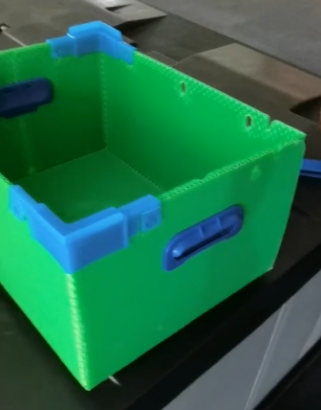

Assembly diagram of a set of reinforced folded boxes

Anti static injection folded box - Needs to match existing molds, the anti static injection folding box shown in this video,

Dimensions before folded: 600 * 400 * 310mm, dimensions after folded: 600 * 400 * 81mm

As is well known, the injection box mold is fixed, and if the size does not match, you must either find similar or open the mold. In fact, finding similar sizes is difficult and takes a lot of time, and the cost of redeveloping the mold is high, ranging from thousands to tens of thousands of dollars, and the process also takes 1-3 months. From this, it can be seen that there are fewer molds for anti-static injection molded folded boxes, which is even more difficult.

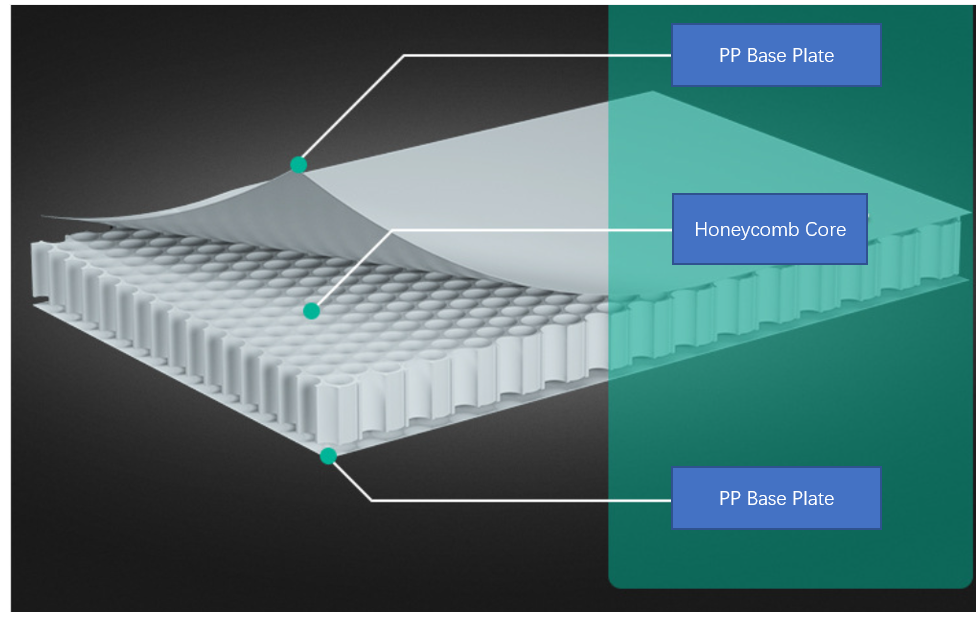

To solve these two major challenges together, we have developed an alternative solution, which is to use anti-static honeycomb boards as materials for customized processing and production, without the need for molds, to produce similar effects as anti-static injection boxes.

At present, there are two thicknesses of anti-static honeycomb boards available (4mm and 10mm), which can meet the expectations of more than 60% of users.

The anti-static honeycomb board, with its stable honeycomb structure, makes the board hard, durable, and has strong load-bearing capacity; Due to its stable surface resistance value, it has become a sturdy, durable, and customizable high-quality material for making anti-static honeycomb board folded boxes

Structure diagram of anti-static honeycomb board:

Side view of anti-static honeycomb board:

Option 3: Riveting machine equipment+anti-static corrugated box assembly accessories, reducing volume by more than 60%

When customers are willing to purchase a riveting machine to operate and assemble themselves, this solution has the smallest transportation volume.

We can purchase riveting machines on behalf of others;

The list of product assembly accessories is as follows:

Semi finished anti-static hollow board;;

Supporting anti-static edge strips and corners;

Rivets required for riveting machines.

Riveting machine image:

Pictures of anti-static corrugated box accessories: